How to Overcome the Luminance-Cost Hurdle for Automotive Intelligent Signal Display (ISD)

As autonomous driving and connected vehicles evolve, exterior automotive lighting is moving beyond illumination and signaling to become a smart, interactive communication interface—accelerating the adoption of automotive Intelligent Signal Display (ISD) technologies.

As this transformation positions exterior lighting as a core vehicle communication layer, Intelligent Signal Display (ISD) is emerging as a pivotal enabler of Software-Defined Vehicles (SDVs) and autonomous mobility. This article explores the engineering challenges, technology options, and supply-chain considerations behind delivering high luminance performance and distinctive visual expression in next-generation automotive ISD applications.

Why is Intelligent Signal Display (ISD) Now Essential for L3 Autonomy and Brand Differentiation?

The shift toward Software-Defined Vehicles (SDVs) and Level 3 autonomy is redefining exterior lighting. For OEMs and Tier 1s, lighting is no longer just about visibility—it’s a key interface for communication and brand expression.

Intelligent Signal Display (ISD) has evolved into a dual-purpose external HMI, serving both safety and design needs. It enables:

- V2X communication – conveying autonomous intent and enhancing pedestrian and ADAS safety.

- Brand identity – allowing dynamic, high-resolution light signatures, welcome animations, and personalized visual effects.

Delivering this blend of functionality and style requires precise engineering: achieving high luminance for all-weather visibility while managing heat and maintaining fine pixel resolution. Striking this balance is the central challenge to realizing next-generation ISD in mass production.

Component Dilemma: Why Tier 1s Choose Mini-LED & LED for Exterior Automotive ISDs

Selecting the optimal display technology for exterior automotive Intelligent Signal Display (ISD) applications requires a careful balance of image quality, brightness, long-term reliability, and manufacturing scalability. While multiple display technologies are available, their performance diverges significantly when deployed in exterior, safety-critical automotive environments. The following comparison outlines the most widely adopted ISD display solutions— Mini-LED/ LED, OLED, and Micro LED, evaluated across key criteria including visual performance, peak luminance, operational lifespan, and cost efficiency.

Feature | OLED | Micro LED | Mini LED/LED (Optimized Solution) |

| Image Quality | Uniform surface light source, yet unable to realize pixel level control | Excellent contrast and high resolution | Excellent resolution with fine-pitch control, high brightness for exterior displays. |

| Max Brightness | Moderate; optimized for interior contrast | Ultra-high; excellent visibility | High peak brightness suitable for exterior visibility |

| Lifespan / Burn-in | May show image retention over time | Longest; robust inorganic material | Long, stable operating lifetime. High reliability for exterior conditions |

| MPR & Cost | Mature, with higher cost at large sizes | Now still high cost in production | Scalable, cost-efficient, and full MPR readiness |

OLED delivers good contrast and is well-suited for interior and aesthetic displays. However, exterior signaling places greater emphasis on brightness stability and long-term durability. Micro LED is widely regarded as the future benchmark, but its current production maturity and cost structure limit near-term deployment in large exterior modules.

Given today’s engineering and manufacturing landscape, Mini LED & LED package offer the most practical balance. It provides strong outdoor brightness performance, robust lifetime characteristics, and scalable cost structures, along with the fine resolution needed for dynamic and legible Intelligent Signal Display (ISD) content. As a result, Mini LED & LED stand as the most commercially viable and technically ready option for current-generation ISD applications. Watch the video to learn more about the processes, structures and benefits of i-mini and mini-like series.

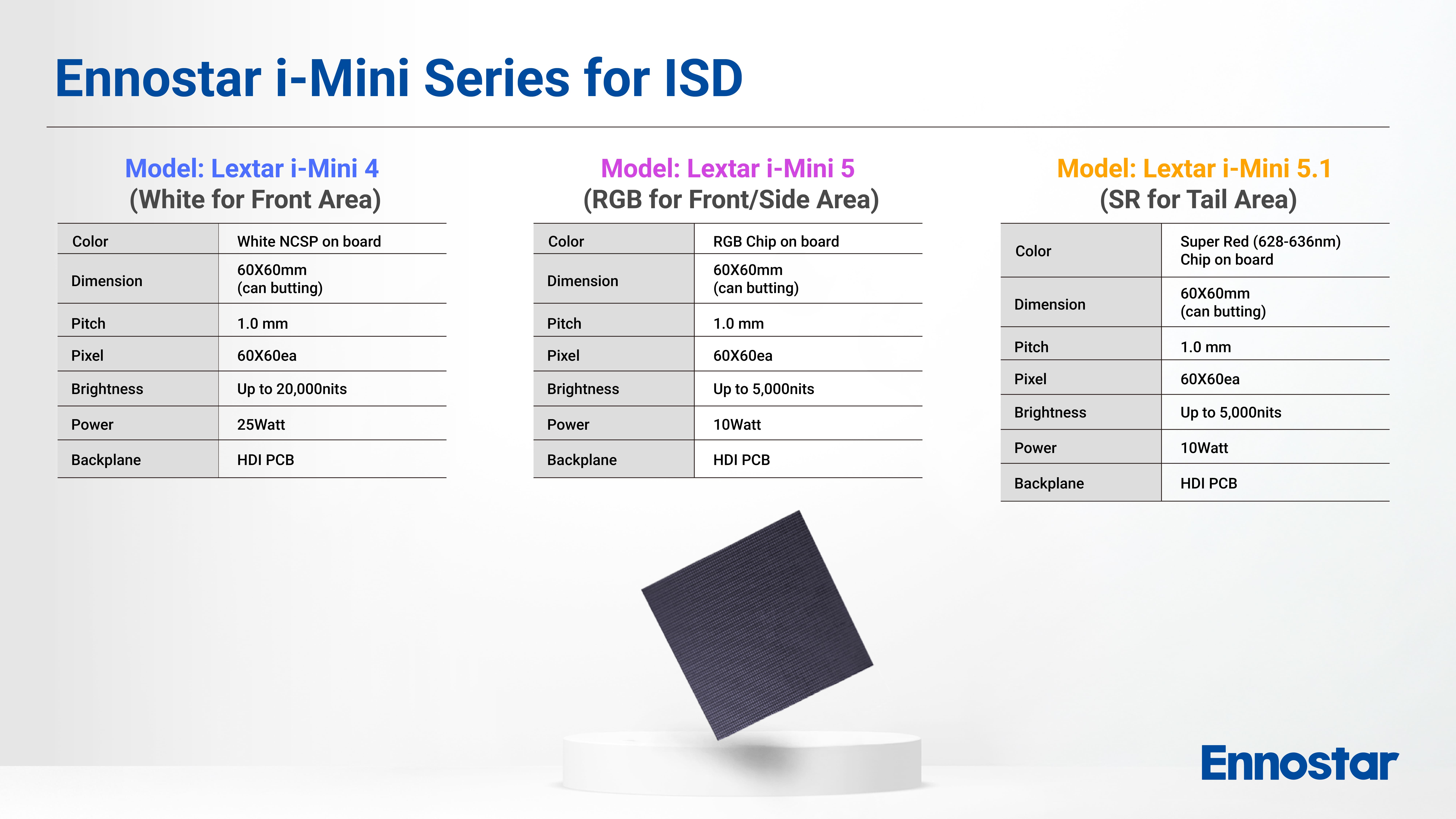

| Ennostar Series | Pitch Option (Approximate) | Design Type | Primary Performance Focus | Ideal ISD Application Focus |

| Mini-like | 4 mm | POB (for Large Emitting Surface) | Highest Brightness & Cost Efficiency. Optimized for max light output per unit cost. | Large-Area Signaling, Basic Warning Indicators, Simplified Graphics. |

| Mini-like | 2-3 mm | POB (for Large Emitting Surface) | Balanced Performance. Strong blend of resolution and cost; enhanced contrast. | Mid-Resolution Messaging, Dynamic Turn/Braking Patterns, Refined Design Aesthetics. |

| i-Mini | <1 mm | COB (Chip-on-Board) | Maximum Visual Precision & Resolution. Superior uniformity, sharp edges, smooth animation. | Advanced eHMI/V2X Messaging, High-Resolution Graphics, Compact/Complex Integration. |

Supply Chain Security: How Ennostar’s Vertical Integration Guarantees Quality and Reliability for ISD

The reliability of a vehicle’s exterior signaling is non-negotiable. Ennostar’s advantage lies in its vertical integration capability from in-house chip manufacturing. This control ensures supply security and allows us to provide specialized solutions, including a market-leading super-red solution (628–636 nm), crucial for maximizing visibility and compliance in demanding tail lamp applications. This expertise positions Ennostar as the No. 1 provider in the automotive amber and red lamp LED chip market, with a global market share exceeding 50%. Ennostar's ISD solution has been adopted by OEM brands and concept demonstration by Tier 1, demonstrating its trusted reliability.

Ready to Deploy? Schedule Your Technical Consultation on ISD Implementation

Are you ready to optimize your next-generation automotive lighting program?

We invite R&D and engineering teams to engage directly with our specialists to define the ideal i-mini or mini-Like configuration for your specific ISD requirements. Contact Ennostar’s automotive solutions team today to schedule a technical consultation.