Build happy enterprises

by caring for and supporting employees

※ With effect from October 1, 2025, one of our main subsidiaries, "EPISTAR", has been officially renamed "Ennostar Corporation".

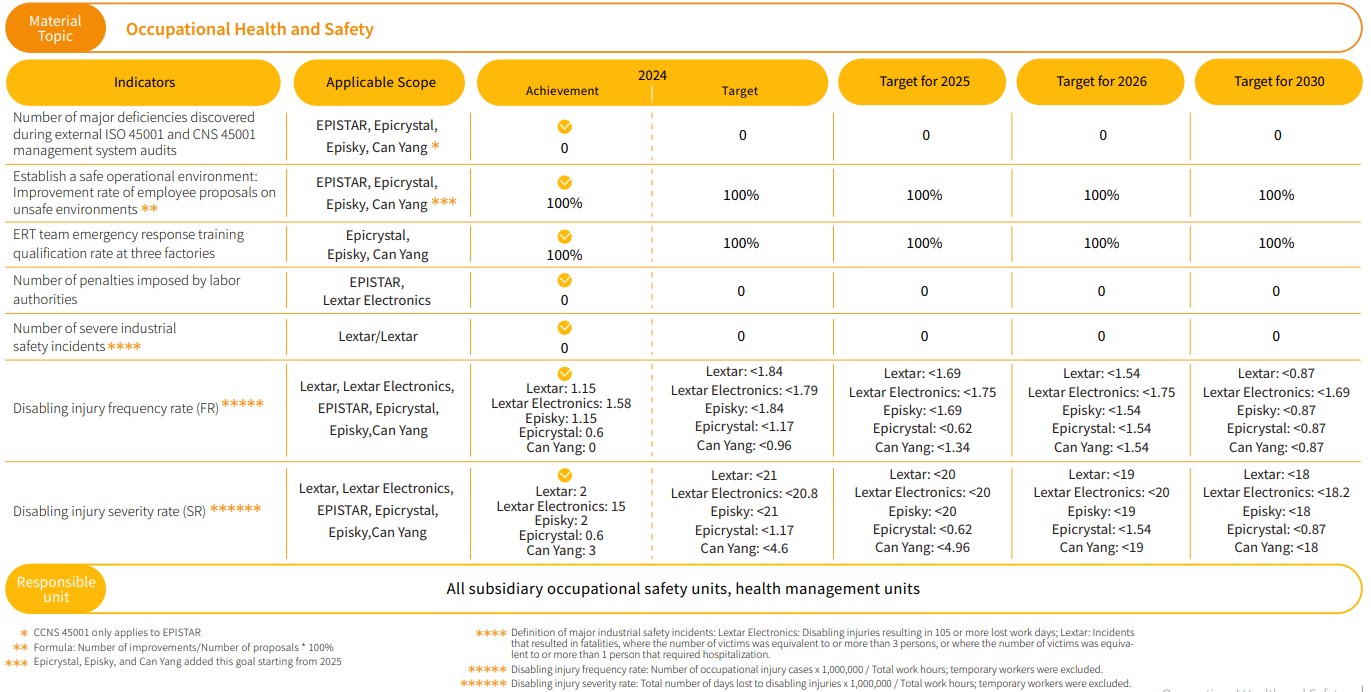

The Ennostar Group strives to promote a culture of health and safety which uses a comprehensive occupational health and safety management system to protect the health and safety of all employees and contractors, thereby preventing occupational injuries and diseases. We established the “EHS Management Manual” and “Environment, Health and Safety Principles,” and also formed the “Environment, Health and Safety Committee” in accordance with ISO 45001, ethical and human rights codes of conduct, local regulations, EHS system regulations (ISO 14001, ISO 45001, CNS 45001) to implement identification, assessment, and control of work environment and operational hazards. All departments conduct analysis of health and safety hazards so we can keep informed of hazards in production processes, factory systems, equipment, and all operations, and can actively prevent occupational hazards and achieve occupational health and safety goals.

All Group subsidiaries have established environment, safety and health (ESH) committees to discuss and coordinate ESH matters, formulate targets, and continue to promote improvement plans. We have established complete contractor management regulations as well as hazard identification, risk assessment, incident investigation, and emergency response procedures. We also strengthen safety risk awareness in our employees and contractors through rigorous occupational health and safety training, emergency response drills, and hazard communication courses.

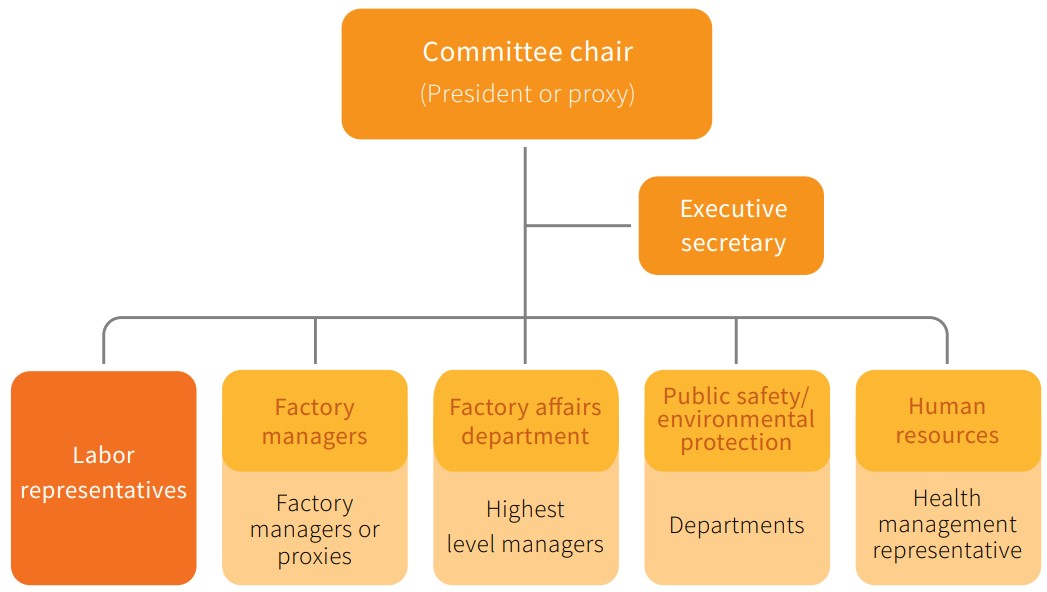

The Group’ s ESH Committee is convened each quarter by presidents or proxies. Factory-level ESH committee meetings are convened at least once every month by factory managers and meeting conclusions are applicable to all factories. Meeting attendees include committee members such as factory managers or proxies and the highest level managers from the R&D, support, quality assurance, and human resource centers; environmental safety department representatives; and labor representatives, who are required to exceed more than one-third (33%) of committee members.

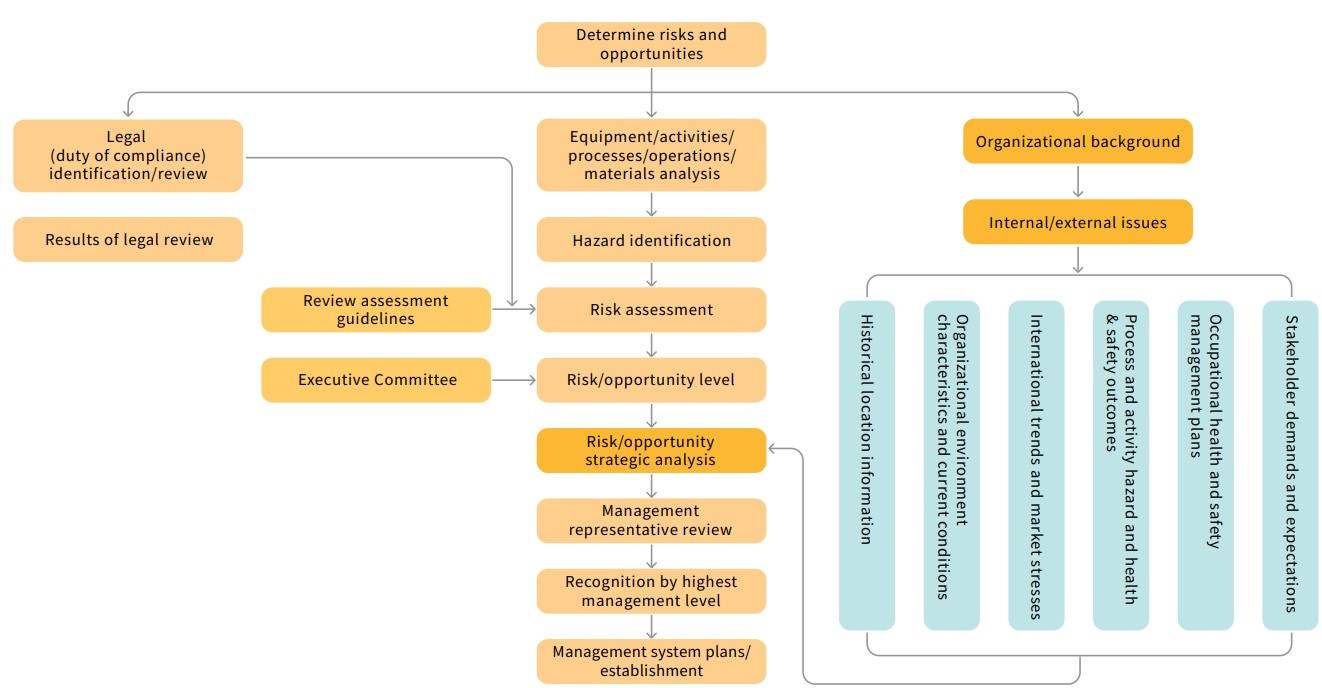

The Group has formulated identification and risk assessment procedures for major hazards. We analyze potential risks that could result in abnormalities using risk assessment technologies and have adopted preventive measures to lower probabilities and severity of hazards. Analysis of health and safety hazards are conducted in accordance with the activities/processes/scope of each department and associated steps/machinery and equipment/work items and other operational procedures. We classify physical, chemical, biological, ergonomic, social, and other types of hazards, estimate their probabilities of occurrence, exposure risks, and levels of severity to identify risks and opportunities.

The Group attaches great importance to the occupational safety of employees. We promptly implement notification procedures at the first instance a er abnormal incidents have occurred and initiate emergency response mechanisms to reduce personnel injuries and operational losses. We have established “Incident Notification and Investigation Procedures” to be adopted following incident occurrence. Incident investigations are conducted with labor representatives to discover root causes of incidents, and this information is used to formulate corrective and preventive measures. Incident investigation reports are simultaneously submitted to the safety committees of all factories, and we expand disclosures of investigation results when necessary to serve as a reference for implementing improvements at each factory and to prevent similar incidents from reoccurring.