Use innovative technologies

to provide cutting-edge service quality

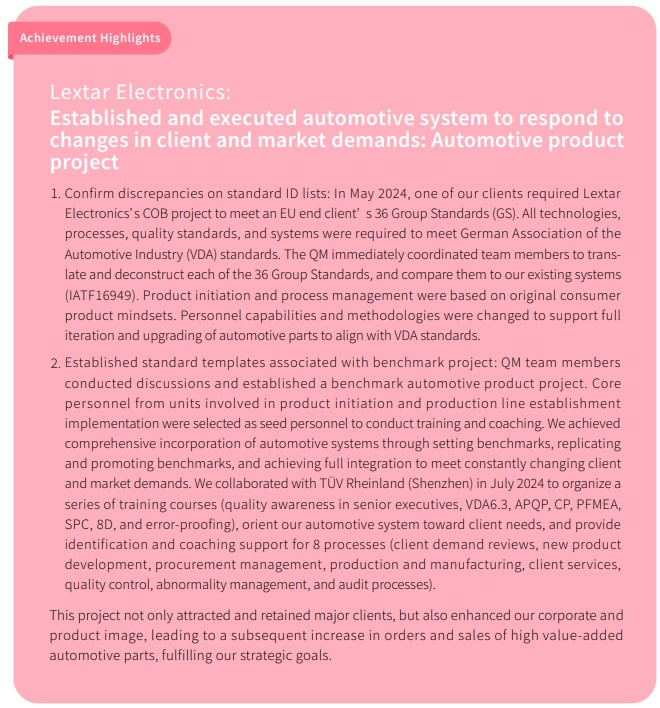

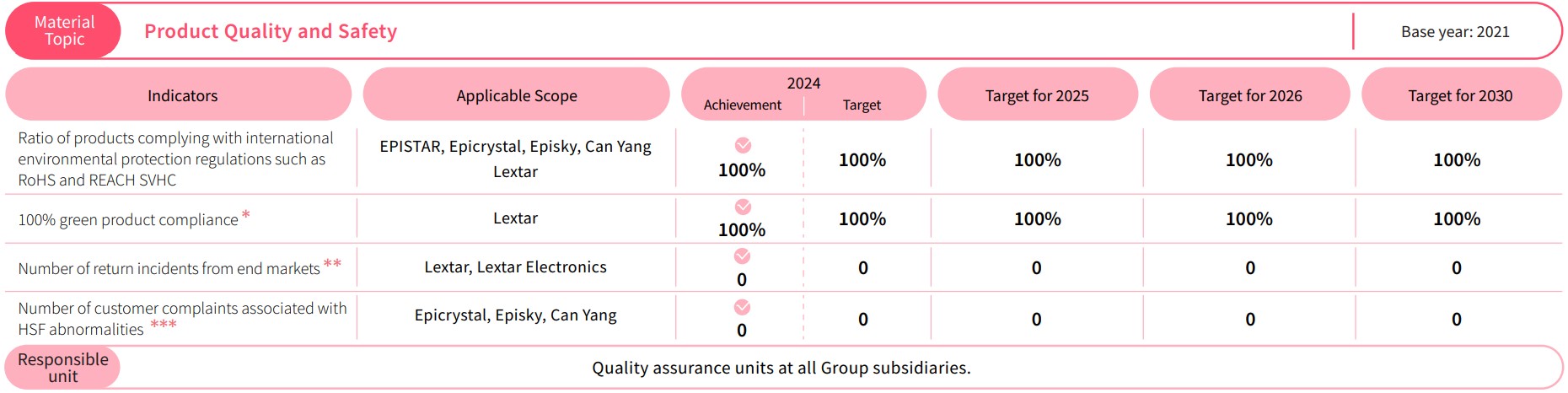

Continued improvement is a fundamental value upheld by the Group. Our long-term goal is to establish a quality culture involving all employees to ensure continued improvement of our products and services. We constantly seek out opportunities, identify problems, and explore innovative solutions through continued improvement activities. We believe that everyone can be a guardian of quality and encourage all employees to enhance their quality awareness and actively participate in continuous improvement processes. We review customer complaints through monthly quality meetings, track incorporation of improvement measures, and check whether issues reoccur to ensure the e ectiveness of our improvement measures. Additionally, we audit our internal management procedures each year to ensure that our quality management systems are working e ectively. We strive to optimize our quality verification processes to strengthen innate product properties and reliability. We comprehensively optimized test coverage rates and test detection capabilities to curb production and outflow of defective products, and also strengthened process capabilities to enhance process stability and precision while continuing to reduce product quality risks to ensure that our products and services meet the highest quality standards and continue to meet client needs and expectations. The Group has obtained external certifications for ISO 9001 and IATF 16949 quality management systems. Lextar and Lextar Electronics have obtained ANSI/ESD S20.20, and respectively obtained external ISO 26262 and ISO/IEC 17025 certifications. Lextar and Lextar Electronics introduced VDA 6.3 in 2024, conducting internal and external education and training, including training for 44 employees who went on to obtain VDA internal auditor certificates, thereby strengthening automotive product management. Lextar and Lextar Electronics also simultaneously executed digital and smart facility management, leveraging departmental collaboration to integrate smart quality management into product lifecycle processes. Smart controls enable e ective management of quality abnormalities and management optimization to maximize benefits. Our long-term plans promote equipment leveling/dedicated line production, and we continue to refine international automotive industrial standards and optimize the quality of automotive products.