Commit to low-carbon transformations to

become a green practitioner and realize environmental sustainability

※ With effect from October 1, 2025, one of our main subsidiaries, "EPISTAR", has been officially renamed "Ennostar Corporation".

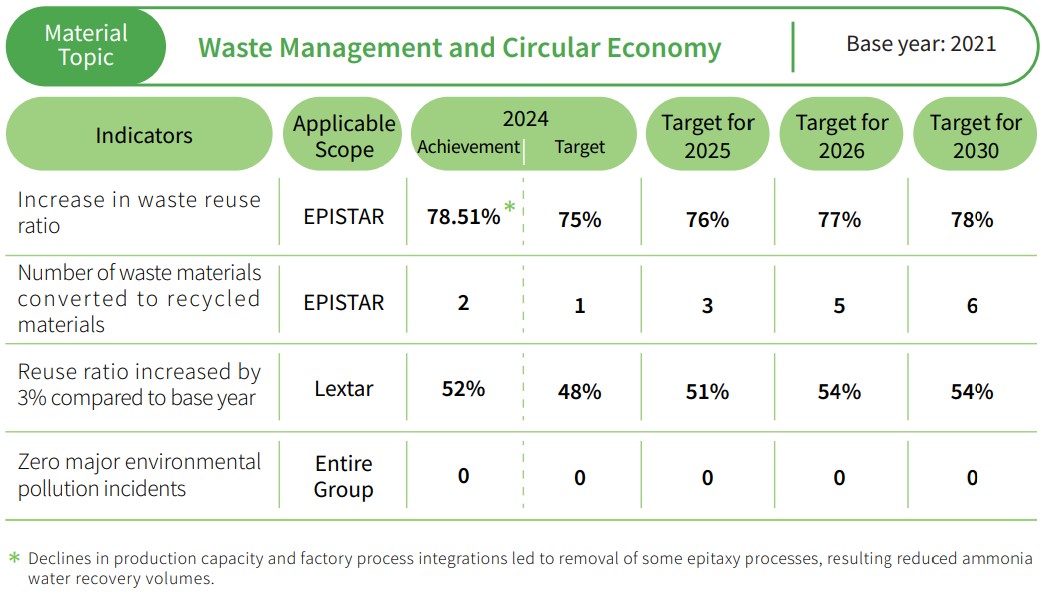

Implementation results for the waste materials converted to recycled materials indicator shown in the table above encompass foam recycling and SRF waste reuse measures implemented in factories in 2024; we also completed assessments regarding the feasibility of recycling gallium waste and plan to commence implementations in 2025. All Group factories have established “Waste Management Procedures” and production processes comply with regulations. Waste is classified, managed, and stored based on protocols at each production stage, and is disposed of by qualified vendors to ensure that waste generated during factory operations are treated legally, appropriately, and safely to minimize environmental impacts. We have also established “Supplier/Contractor EHS Appraisal Regulations” which stipulate that we only collaborate with qualified waste disposal companies which have passed our checks. Ennostar regularly conducts supplier audits to ensure that collaborating suppliers dispose of waste in accordance with contracts and regulations. The Group balances economic activities and environmental ecology by inventorying and recording output volumes and handling methods for di erent types of waste, and continues to identify waste reduction and reuse opportunities in all production processes. For example, we seek out potential collaborating vendors for waste recycling and reuse technologies to increase recycling rates and reduce non-recyclable waste which is handled using incineration, solidification, or landfill. We collaborate with industry, government, and academic institutes to convert waste into new materials and resources; incorporate green design concepts and improved processes; and recycle and reduce organic solvents, exhaust emissions, and metals while working with suppliers to assess feasibility of recycling measures for hazardous substances. We use sustainable raw materials, reduce material consumption, and enhance product yields to lower production costs and enhance eco-friendliness of production processes. We also continue to implement waste classification, waste recycling, and packaging material reuse measures to reduce waste, and utilize the PDCA cycle for continued improvements.